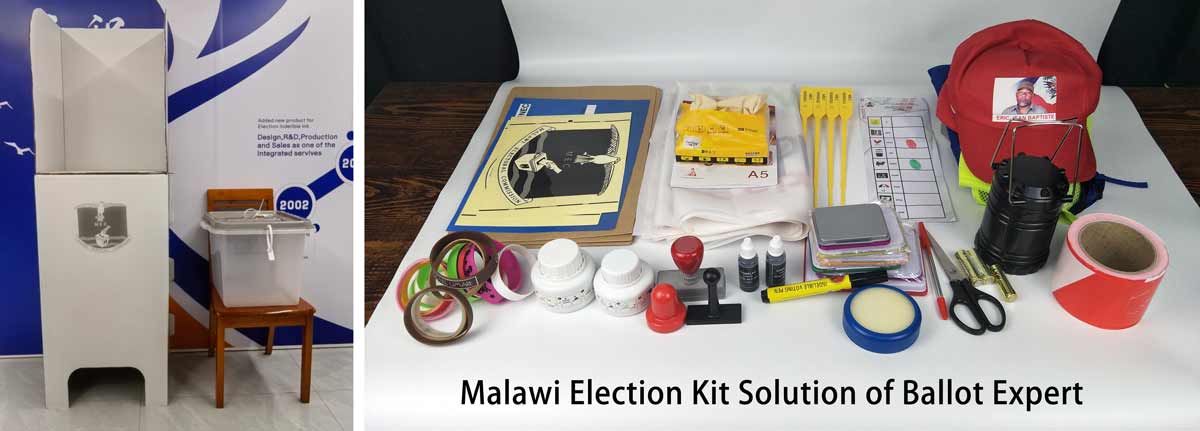

The voting materials for Malawi's 2025 general election cover the entire process from plastic ballot boxes, cardboard polling stations to ballots, and the equipment and materials required for voter ink. Its procurement, technical standards, and distribution management not only reflect international cooperation, but also face many challenges of localization.

1. Core Material List and Technical Requirements for Election Kit

(1) Plastic ballot boxes, cardboard polling stations, and ballot printing

The plastic ballot box adopts modular design, involving injection molding, printing, and assembly. Produced by local enterprises in cooperation with overseas suppliers, ensuring waterproof and fireproof performance and equipped with dual locks. The cardboard voting platform is designed and manufactured by election experts. Domestic enterprises participate in the printing of ballots, using anti-counterfeiting ink and secure watermark technology to prevent forgery. MEC plans to print approximately 7.2 million ballots, covering the presidential, parliamentary, and local government elections. However, due to the issue of damaged ballot boxes last time, the quality and performance of the election were affected, leading to suspicion of vote fraud. And this time the cost is higher than most Chinese suppliers, so this global public bidding will particularly focus on inspecting Chinese suppliers.

(2) Election ink and marking tools

The non erasable ink and election markers used for the 2019 voting were provided by election experts, containing 10% silver nitrate to ensure that voters' finger markings do not fade for at least 72 hours. The ink has been tested by an independent laboratory and meets international election standards (ISO 21600), and is packaged in portable squeeze bottles for easy operation by staff.

2. Procurement requirements and supply chain management for election kits

(1) Key equipment: ballot box and polling station. The polling station procures local enterprises from a single source to reduce transportation costs, while the ballot boxes are designed by independent station voting experts and jointly manufactured by Zimbabwe. The main production is undertaken by Chinese factories.

(2) Staff clothing: On the Alibaba platform, Chinese suppliers provide customized voting shirts with election logos and candidate portraits, with a minimum order quantity of 350000 pieces.

(3) Other equipment: The supplier information of the vote counting software has not been made public, but MEC has stated that it will use standardized equipment compatible with EMDs to ensure efficient connection of the vote counting process.

(4) International logistics: The goods arrive in Mozambique via COSCO Shipping and are then transferred to Malawi, where all customs clearance and certification preparations are complete.

(5) Distribution network: Malawi Defense Forces transport convoys are distributed to 28 warehouses nationwide, and then transported by local election officials on motorcycles or boats to remote polling stations. MEC has established a real-time tracking system that can monitor the location and inventory status of materials. Each polling station is equipped with an emergency supplies package, which includes spare ink, batteries, and a manual vote counting table.

3. Challenges and Risk Management of Election Suite Application Technology

(1) The opposition party demands a return to manual vote counting due to device compatibility issues, but MEC insists on electronic systems and has optimized the recognition ability of EMDs for low resolution photos in pilot projects. At present, the equipment has passed the interface test with the national identity card system, ensuring a data synchronization accuracy rate of 99.7%.

(2) Material safety and tamper proof, the ballot box adopts GPS positioning chip to monitor the transportation path in real time; The ballots are immediately sealed and escorted by the police after printing. MEC has also introduced third-party auditing agencies to conduct random inspections of material storage and distribution.

(3) Technology dependence risks, some civil organizations are concerned that excessive reliance on foreign technology may lead to system vulnerabilities, and call for strengthening the participation of local technology teams.

(4) Controversy over procurement transparency, opposition parties accuse ballot box procurement of kickbacks and demand disclosure of supplier contract details. MEC responded that the procurement documents have been submitted to the Anti Corruption Bureau for review, but have not yet been fully disclosed. In addition, the historical controversies surrounding Smartmatic in the Philippines and Kenya continue to raise concerns among some voters.

(5) Voter registration pressure: Although EMDs have improved efficiency, the backlog of national ID cards still needs to be resolved. The government has extended the validity period of ID cards until 2026 to alleviate the pressure.

4. Election experts' innovation and sustainable practices

(1) Application of environmentally friendly materials. The plastic ballot box is made of recyclable plastic, and the cardboard voting table and ballot paper contain 30% recycled fiber. MEC plans to recycle 90% of the materials after the election and transform them into community office supplies through a United Nations project.

(2) Integration of digital tools. Voters can use the ElectionBot chatbot to check the preparation of materials at the polling station, and the system updates ink and ballot inventory data in real-time. The pilot showed that the tool reduced on-site consultation needs by 30%.

(3) Technical stability and public trust. Malawi's voting material system seeks a balance between progressiveness technology and localized practice. As the election approaches, MEC needs to continue to address challenges such as equipment dependence and procurement transparency to ensure the fairness and inclusiveness of the voting process.